Modern Wind Turbines: Specifications, Advantages, and a Historic Case Study

Specifications of Modern Wind Turbines

Modern wind turbines are highly optimized machines with ever-increasing sizes and improved performance. Key specifications of contemporary horizontal-axis wind turbines include:

Size and Power Ratings

- Rated Power Output: Utility-scale onshore wind turbines typically range from about 2 to 5 megawatts (MW), while the latest offshore turbines reach 10–15+ MW in capacitycss.umich.edu

- . For example, the GE Haliade-X offshore turbine is rated around 12–15 MW and features blades 107 m long (about 351 ft) eachenergy.gov

- . Even small-scale models (for home or farm use) exist around 1–100 kW, illustrating the scalable range of wind turbine sizescss.umich.edu

- .

- Rotor Diameter: Rotor diameters have grown dramatically to capture more wind. Modern land-based turbines commonly have rotor diameters on the order of 100–140 m (330–460 ft)energy.gov

- . In 2023, newly installed U.S. turbines had an average rotor diameter of 133.8 menergy.gov

- . Offshore designs are even larger – the largest turbines sweep over 200 m in diameter (e.g. ~220 m for the Haliade-X), enabling enormous swept area and energy captureenergy.gov

- .

- Hub Height: Towers have become taller to access higher wind speeds. Onshore turbine hub heights are often in the 80–120 m range, with a U.S. average of about 98–103 m in recent yearscss.umich.edu

- energy.gov

- . Offshore turbines typically use hubs around 100–150 m above the waterenergy.gov

- . Taller towers take advantage of the fact that wind speed generally increases with altitude (due to reduced ground drag)energy.gov

- .

Performance (Efficiency and Capacity Factor)

- Aerodynamic Efficiency: A wind turbine cannot capture all the energy from the wind – the theoretical maximum efficiency (the Betz limit) is ~59%. Modern three-bladed turbines routinely achieve ≈45–50% aerodynamic efficiency in converting the wind’s kinetic energy into mechanical shaft powercss.umich.edu

- . This is close to the practical limit and a big improvement over earlier designs.

- Capacity Factor: The capacity factor is the ratio of a turbine’s average output to its nameplate (maximum) output. Thanks to improved design (larger rotors, better siting, and controls), capacity factors have steadily increased. On land, wind turbines in the U.S. average around 35–40% capacity factor (with a range roughly 9% up to 50+% depending on wind resource and turbine model)css.umich.edu

- . Newer onshore projects often exceed 40% in windy locations. Offshore wind farms achieve even higher capacity factors – typically 40–50%, and projected to reach 60% for state-of-the-art installations by 2050css.umich.edu

- . These high capacity factors mean modern turbines generate power a large fraction of the time (though output varies with wind speed).

Materials and Structural Components

Wind turbines are built from robust materials to withstand decades of fatigue loading and harsh environments:

- Blades: Most utility-scale turbine blades are made from fiber-reinforced composites, primarily fiberglass embedded in polyester or epoxy resin, often with wood or carbon fiber spars for strength. This yields a lightweight but stiff structure. For large blades (50+ m), manufacturers increasingly use carbon fiber reinforcements to reduce weight while maintaining strength and rigidity. Blades also have protective coatings (gelcoat, paint) to withstand UV, rain, and erosion.

- Tower: Towers are generally tubular steel structures, tapered toward the top. Steel comprises the majority of a wind turbine’s mass (often 65–80% of total mass)usgs.gov

- . Typical tower sections are made of rolled steel plate (e.g. S355 structural steel) welded into cylinders. Some newer towers use concrete (particularly for taller towers or hybrid steel-concrete designs) to reduce cost and ease on-site fabrication. The tower supports the nacelle and rotor, and must handle heavy static and dynamic loads.

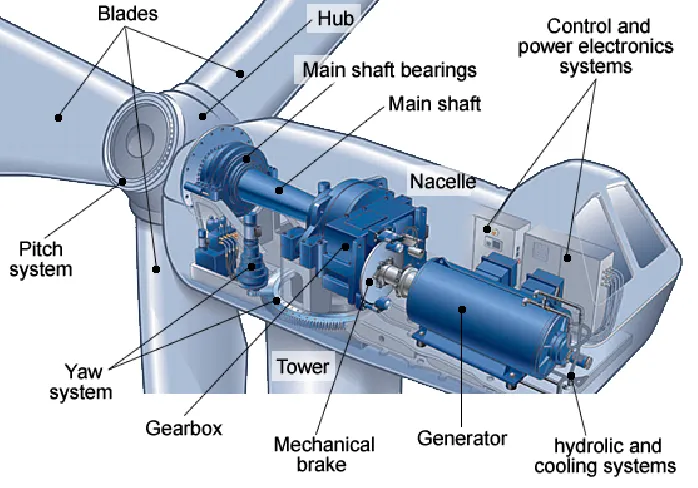

- Nacelle and Internals: The nacelle (the housing at the top of the tower) contains the drivetrain and electrical components. Key parts include the main shaft and bearings, gearbox (unless a direct-drive design is used), generator, and brake. These components are typically high-grade steel and iron (e.g. cast iron bedplate and gearbox housings) for strengthusgs.gov

- . Generators contain considerable copper in windings (copper is ~1% of turbine mass)usgs.gov

- , and high-power permanent magnets in some designs (using rare-earth metals like neodymium). The nacelle is usually covered by a fiberglass or polymer shell to protect it from weather. Overall, a modern turbine is roughly 66–79% steel, 11–16% fiberglass/plastic, 5–17% cast iron, ~1% copper, plus small fractions of aluminum and other materialsusgs.gov

- .

- Foundations: Onshore turbines use large concrete foundations (hundreds of cubic meters of reinforced concrete) anchored in the ground to support the tower. Offshore turbines use specialized foundations – for example, monopiles (steel piles driven into the seabed) or gravity-base platforms – designed for the marine environment and water depth.

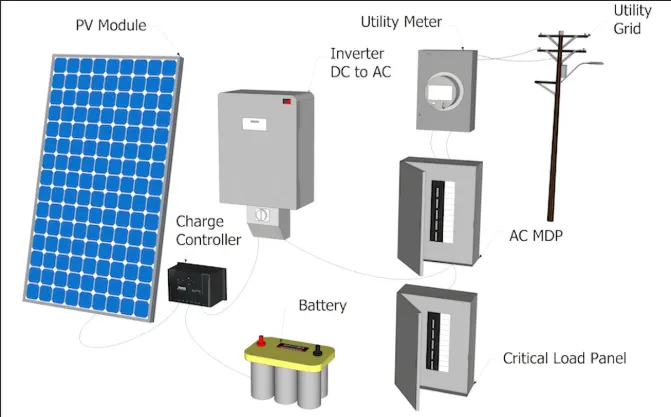

Control Systems and Grid Connectivity

Modern turbines employ advanced control systems to optimize performance and ensure safe, grid-compliant operation:

- Yaw Control: Utility-scale turbines are typically upwind designs that must face into the wind. A yaw drive, powered by electric motors, actively rotates the nacelle to track wind directionenergy.gov

- . A wind vane on top of the nacelle measures wind direction and feeds that data to the controller, which then engages yaw motors to keep the rotor aligned with the wind.

- Pitch Control: The pitch control system adjusts the angle of the blades (pitch) along their longitudinal axis. By pitching blades, the turbine controls how much lift they generate. In normal operation, active pitch control maximizes power capture at lower wind speeds and then feathers (partially turns out) the blades to limit power at the rated level in high windsenergy.gov

- . Pitching is also the primary braking mechanism: in dangerously high winds, blades are fully feathered (turned parallel to the wind) to stop rotationenergy.gov

- . Modern turbines have individual blade pitching via hydraulic or electric actuators, and even use backup power (e.g. battery or ultracapacitor systems) to ensure blades can pitch to a safe position during grid lossregenpowertech.com

- .

- Electronic Controller and SCADA: A central microprocessor-based controller monitors the turbine’s status (using sensors for wind speed, wind direction, rotor speed, vibration, temperature, etc.) and governs all operations. It handles startup, shutdown, yaw, pitch, and fault detection. Turbines are usually part of a Supervisory Control and Data Acquisition (SCADA) network, communicating with a farm-level control system or remote operatorsregenpowertech.com

- . This allows dozens or hundreds of turbines in a wind farm to be monitored and controlled from a central control room. Parameters like power output, wind conditions, and component temperatures are logged in real-timeregenpowertech.com

- . The SCADA system can implement curtailment commands (e.g. to shut down turbines during grid oversupply or for noise mitigation at certain times) and helps with predictive maintenance by analyzing performance data.

- Drive Train and Power Electronics: Most large turbines today operate at variable speed, using power electronics to interface with the grid. In a typical design, a doubly-fed induction generator (DFIG) or a full-conversion synchronous generator with a frequency converter is used. This allows the rotor speed to vary with wind speed for higher efficiency and reduced mechanical stressregenpowertech.com

- . A frequency converter (AC-DC-AC power electronic device) or converter/inverter system ensures the output electricity is synchronized to grid frequency. The turbine’s main brake (usually a disk brake on the high-speed shaft) serves as an emergency backup to aerodynamic braking.

- Grid Connection: Each wind turbine usually has a step-up transformer (often at the base of the tower or inside the nacelle) to raise the generator voltage (e.g. from 600–700 V up to a medium-voltage collection grid of 33 kV). Power from multiple turbines in a farm travels through underground cables to a substation, where another transformer steps it up to high voltage (e.g. 110 kV or higher) for transmissionenergy.gov

- energy.gov

- . Modern wind farms comply with grid codes: turbines are equipped with features like low-voltage ride-through (LVRT), which allows them to stay online during short voltage dips and not trip off at the first sign of grid disturbancesregenpowertech.com

- regenpowertech.com

- . They can also provide ancillary services – many turbine controllers can supply reactive power (voltage support) through their inverters and can even perform frequency response by adjusting output or emulating inertia. In essence, wind turbines now behave much like conventional power plants in grid interaction, facilitated by intelligent controls and power electronics for smooth grid connectivity.

Technical Advantages of Wind Turbines

Modern wind turbines offer numerous technical and economic advantages as a source of energy:

- High Efficiency at Variable Wind Speeds: Turbines are designed to efficiently convert a wide range of wind speeds into electricity. Techniques like variable-speed operation and active blade pitch control enable optimal energy capture at different wind conditionsregenpowertech.com

- . Larger rotors allow turbines to harvest more energy from moderate winds, expanding the areas where wind power is viableenergy.gov

- . As a result, today’s turbines achieve much higher capacity factors than older models, maintaining efficiency from cut-in (low) wind speeds up to rated wind speeds.

- Low Operating Costs: Once installed, wind turbines incur minimal operating cost since their “fuel” (wind) is free. Maintenance and monitoring are the main ongoing costs, and these have dropped as turbine reliability improves. The levelized cost of electricity from land-based wind has fallen to around $32 per MWh as of 2022css.umich.edu

- , making wind one of the cheapest energy sources. There are no fuel purchases or waste disposal costs, and automation (remote SCADA control) keeps labor needs low. This gives wind farms a stable long-term cost structure with no exposure to fuel price volatility.

- Integration with Smart Grids: Wind farms are increasingly integrated into smart grid systems. Turbine controllers and farm-level software can respond to grid demands in real time, adjusting output or ramping down if needed for grid stability. Modern wind turbines can provide grid services such as voltage regulation and frequency control by way of advanced inverters and controls (for example, by injecting reactive power or performing rapid output adjustments). They are often equipped with communication links to grid operators for automatic generation control signals. Moreover, wind farms can be paired with energy storage or other renewables in a smart grid, helping to smooth out variability. In essence, wind power is a flexible participant in modern grids, not a passive energy source.

- Environmental Benefits: Wind energy has among the lowest environmental impacts of any power generation method. During operation, wind turbines produce no greenhouse gas emissions or air pollutantscss.umich.edu

- . Unlike fossil fuel plants, they consume no water for cooling and release no harmful byproducts. The overall land footprint is small – a typical wind farm uses about 85 acres per MW, but 95–99% of that land remains available for farming, grazing, or other uses (turbine foundations and access roads occupy only ~1% or less)css.umich.edu

- . While there are some concerns (such as bird/bat collisions and visual impact), mitigation strategies and careful siting can minimize these issues. Over their life cycle, wind turbines emit only a few grams of CO₂ per kWh generated (from manufacturing and installation), dramatically lower than coal or gas plants. This excellent environmental profile makes wind a key tool for reducing carbon emissions and combating climate change.

- Scalability and Modular Deployment: Wind energy is highly scalable. Projects can range from a single turbine powering a remote facility to sprawling wind farms of hundreds of turbines. This modular nature allows capacity to be added in increments, providing flexibility in expansion and financing. Turbines are manufactured in factories as modular units, which are then transported and assembled on site, enabling rapid deployment compared to traditional power plants. Wind farms are also geographically distributable – they can be installed wherever there is a good wind resource, spreading generation across a region and increasing grid resilience. The ease of adding more turbines means operators can start with a smaller project and expand over time. Additionally, if one turbine goes offline, the others continue operating, providing inherent redundancy in a multi-turbine wind plant.

Case Study: Vindeby Offshore Wind Farm (1991)

One historically significant wind energy project is the Vindeby Offshore Wind Farm, the world’s first offshore wind farm. This project, installed in 1991 off the coast of Vindeby (Lolland island) in Denmark, marked a pivotal moment in wind power engineering.

Project Overview: Vindeby was a small demonstration wind farm comprising 11 turbines mounted in shallow Baltic Sea waters about 1.5–3 km from shoretethys.pnnl.gov

. The turbines were Bonus Energy B35/450 models – at the time, the largest onshore turbines available – each rated at 450 kW capacitytethys.pnnl.gov

. Key technical specifications of the Vindeby turbines included a 37 m rotor diameter and 37.5 m hub height on fixed gravity-base foundationstethys.pnnl.gov

. The wind farm’s total installed capacity was 4.95 MW (quite modest by today’s standards)climateaction.org

. A single 10 kV undersea cable exported the power to shoretethys.pnnl.gov

, where it connected into the local grid. The turbines were arranged in two rows and could collectively produce on the order of 9–12 GWh per year, supplying electricity to roughly 2,200 households in Denmarkorsted.com

Year of Installation: Construction of the wind farm took place in 1991. All 11 turbines were erected in a span of just 11 days in the summer of 1991, reflecting the efficiency of modular turbine installation even in early offshore projectsen.wikipedia.org

. The project became fully operational in September 1991tethys.pnnl.gov

. It was developed by the utility SEAS and Elkraft (predecessors to DONG Energy, now Ørsted) with support from the Danish government as a pilot to test offshore wind technologyen.wikipedia.org

. The entire project cost around 75 million DKK (about $10 million USD)en.wikipedia.org

.

Technical Highlights: As an engineering endeavor, Vindeby tested whether standard wind turbines could withstand a marine environment. The turbines were essentially adapted onshore units, placed on concrete caisson foundations in water 2–5 m deepclimateaction.org

. They had to endure salt corrosion, wave forces, and strong sea winds. Each turbine featured pitch-controlled blades and active yaw – technologies already present in 1991 on Danish turbines – and were connected via the simple 10 kV grid. The site’s mean wind speed was lower than some later offshore sites, resulting in a capacity factor of around 22–25% over its lifetime (each 450 kW turbine averaged about 0.1 MW output)en.wikipedia.org

. Maintenance crews accessed the turbines by boat, learning how to service machines offshore. Despite modest performance, the turbines operated reliably for 25 years.

Impact and Legacy: Vindeby Offshore Wind Farm proved the feasibility of offshore wind power. Initially, many in the energy industry doubted that installing turbines at sea was practicalen.wikipedia.org

. Vindeby’s success in generating power stably for decades helped change that perception. Engineers gained invaluable experience in foundation design, marine logistics, and corrosion protection from this projecten.wikipedia.org

. The lessons learned informed the design of subsequent larger offshore wind farms in the late 1990s and 2000 sen.wikipedia.org

. Vindeby was decommissioned in 2017 after surpassing its 25-year design lifeen.wikipedia.org

. The blades, towers, and nacelles were dismantled and brought to shore for recycling and reuse in research projects climateaction.org

. One of the original Vindeby turbines was preserved for display at the Danish Museum of Energy as a historic artifact

. The project is widely regarded as “the beginning of today’s global offshore wind power industry”climateaction.org

, demonstrating on a small scale what is now a vast and rapidly growing sector. Today’s enormous offshore wind farms – with individual turbines exceeding 10 MW – trace their lineage back to the engineering pioneering done at Vindeby, which validated that wind turbines could successfully operate in the harsh offshore environment and pave the way for a new era in renewable energy.

Vindeby at a Glance: Nameplate Capacity: 4.95 MW (11 × 450 kW). Location: Off Lolland, Denmark (Baltic Sea, ~2 km from shore). Turbine Specs: 35–37 m rotor, 35 m hub height, Bonus 450 kW unitstethys.pnnl.gov

. Installation Year: 1991 (operational through 2017). Significance: World’s first offshore wind farm; proved viability of offshore wind, leading to larger projects worldwidenorthcoastoffshorewind.org

.

Sources: Wind turbine specifications and performance data were gathered from U.S. Department of Energy reports, engineering factsheets, and materials science references. The Vindeby case study details are drawn from project archives and retrospective analyses by organizations like Ørsted and the U.S. National Renewable Energy Laboratory. All technical information and data points are cited in-line with reputable sources.